The Greatest Guide To Steel Road Plates

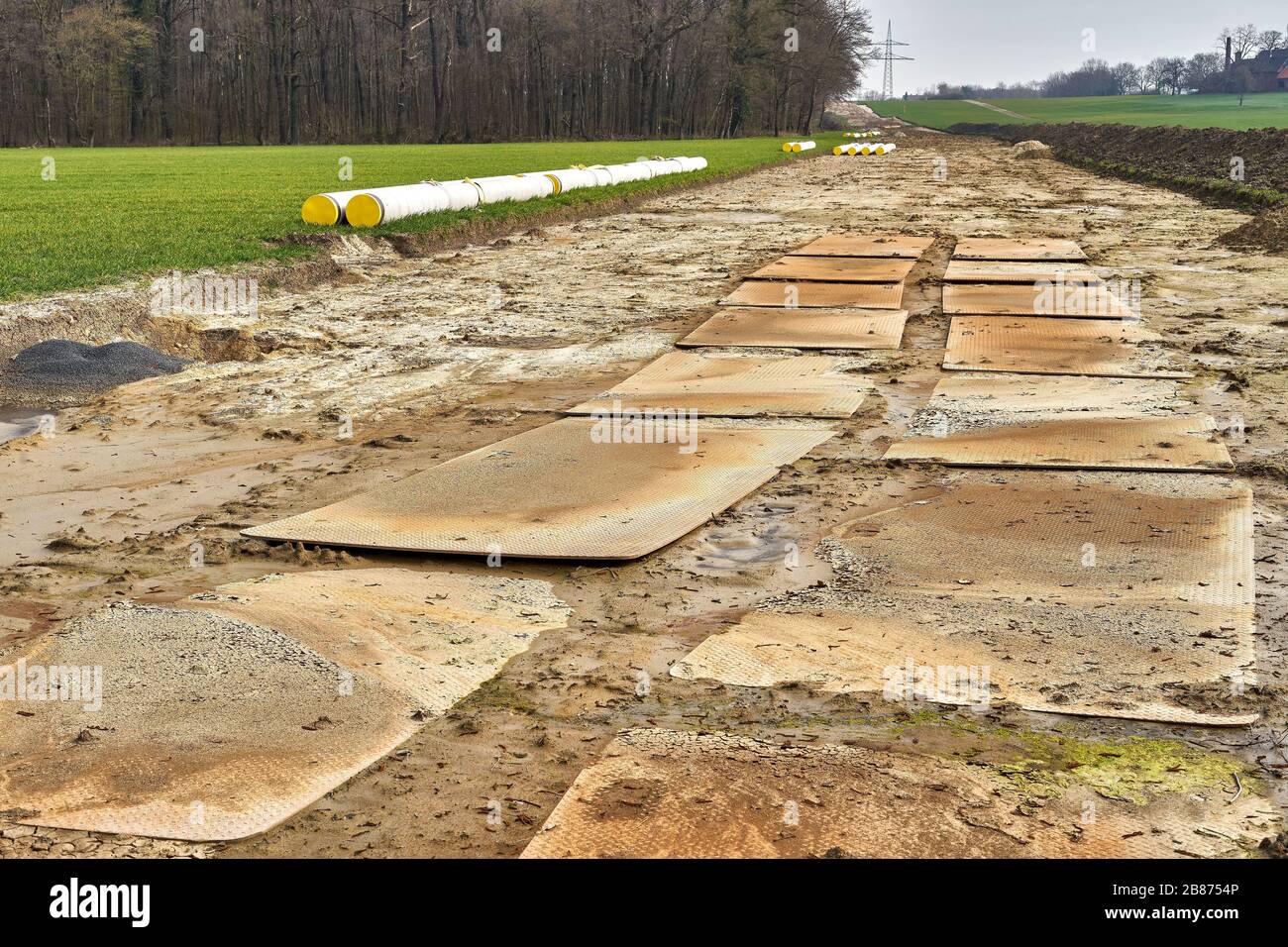

These durable, durable plates permit roadways to return to solution so that building and construction can continue. These plates can be made use of to make certain that roadways can still be used whilst other stages of job continue.

They offer a perfect concession for maintaining lanes, whilst job proceeds overnight and at weekend breaks. They are often seen when excavations have actually started as an onset of construction or fixing projects. These plates are designed to hold up against durable use on active roads. They feature an akti-skid coating and are readily available in a variety of colour finishes - Steel road plates.

The weights start from around 300kg and conventional roadway plates have a density of either inch or inch. The capability to be bolted to the road.

More About Steel Road Plates

Hinged versions for fast accessibility to the excavation or normal gain access to, e.g. driveways. Composite plates, which can fit different sizes of trench. For this factor, they ought to be mounted making use of a forklift or crane.

Examine for displacement by web traffic packing from the start plates must always stand up to displacement. Inspect that home plates do absent a danger to any type of kind of road individual and can be made use of by all roadway users and automobile kinds, consisting of pedestrians, bikers and motorcyclists. Produce a normal evaluation and upkeep to make certain that performance stays secure and maximum.

Repair home plates appropriately in any way times. Mechanical lifting makes certain that the plates are mounted precisely and securely. The right plates must appropriate for the preferred purpose Take into consideration proper security areas, specifically when intending installation. The weight of the plates can trigger turning in the building location or throughout neighbouring carriageways/ footways.

If a ramp is produced by the roadway plates, after that alerting indications for pedestrian and roadway customers are needed. Always a conduct complete site study, and take the specialist recommendations of a structural engineer.

The 2-Minute Rule for Steel Road Plates

In order to improve safety and security, there are a number of criteria and industry documents leading their use in building and construction job areas. Steel plates must be repaired in place to avoid motion.

What Does Steel Road Plates Mean?

Along with being firmly touching the sidewalk, they must be either pinned, recessed right into the pavement, or safeguarded with asphalt wedges around the border. Pinning right into the pavement includes driving pins right into the sidewalks along the sides of the steel plates to avoid motion. Recessing entails removing the area where the steel plate will certainly be positioned.

This leads to the steel plate being flush with the pavement. Furthermore, when several steel plates are used and butt approximately each other, they must be welded together at the longitudinal joints. Steel plates can be really unsafe, especially when they are damp, unless they have an anti-skid finishing applied.

Treatment steel plates with a material that boosts friction aids motorcyclists and bicyclists keep control, especially in damp climate. Problems which decrease sidewalk rubbing in job areas are of particular issue to motorcyclists and bicycles. A common risk in steel plate installations happens when the customer stops working to construct appropriately tapered ramps from the street to the edges of the steel plate( s).

Steel Road Plates Fundamentals Explained

It presents a significant risk to motorcyclists and bicyclists that can quickly blow up when discover here they call the abrupt/steep tapered ramp and the steel plate. Properly tapered ramps permit users to securely cross over the steel plates. Tapers for steel plates are normally created of asphalt. The taper lengths vary from State to State and typically array from 20 basics to 1 to 120 to 1 (Steel road plates).

Make certain appropriate overlap. Generally, steel plates have to extend at the very least one foot past the pavement opening onto company ground.

What Does Steel Road Plates Do?

Welding is used when greater than one steel plate is utilized and they butt approximately each other. Plates should be countersunk when necessary because of irregular roads. Plates need to be covered with an anti-skid finish. The sides of the steel plates ought to be marked/painted to improve visibility. Correct development indication ought to be used.

His history includes the building, evaluation, read more.

Worldwide of civil engineering and building and construction, steel road layers are an essential tool that holds enormous significance. These durable steel plates play a vital duty in improving construction safety, providing temporary roadways, and making certain smooth operations on different project sites. As a construction tools provider, their importance can not be overemphasized.